Who We Are

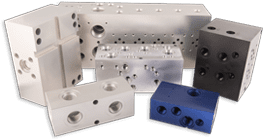

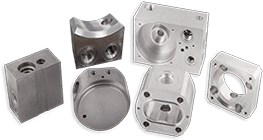

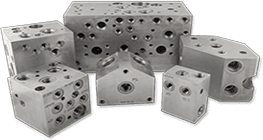

New Dimensions Precision Machining is a Global Sourcing Solution that specializes in machining hydraulic manifolds/ valves, hydraulic cylinders, and machined castings. Production capabilities feature 40 stand-alone CNCs and 20 palletized automated CNC horizontal mills. Internal value-added services include thermal deburring, parts washing, and assembly. New Dimensions machines 40,000 to 50,000 units monthly consuming over 4 million lbs. of aluminum and 3 million lbs. of ductile iron and steel annually.

Learn more about our capabilities below:

Get Every Part Right

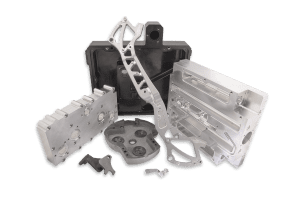

Aluminum Manifolds

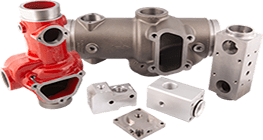

Cylinders & Pumps

Iron Manifolds

Hydraulic Valves

Industrial Valves

General machining

New Dimensions Updates

Machine Upgrade

Our new 14 pallet magazine is a great upgrade, adding more lights out and flexibility to this 500mm Makino A61 milling center.

National Donut Day!

NFPA Youth Fluid Power Challenge

The NFPA's Fluid Action Challenge is a great way to introduce middle-school age children to hydraulics and pneumatics. New Dimensions-PMG is proud to have helped sponsor and participate in the McHenry County event. With over 120 children participating, the day was a...

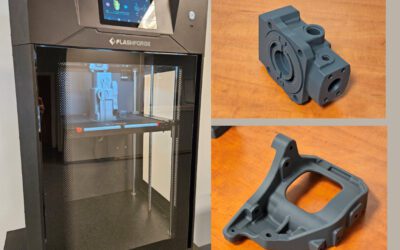

3D Printer

Our new 3D printer allows us to create models of complex parts to assist in quoting and manufacturing planning. These models also help us reduce part launch time by testing fixtures and CMM programs before the actual material and machined parts are available.

New Machines are Here

The new Makino A51nx machines for our hydraulic valve machining cell have arrived.

Prep for Hydraulic Valve Cell

Cutting in 14" deep concrete pads for an exciting new robotic cell with two machines to manufacture cast iron hydraulic control valves.