Capabilities

Flexible Machining

Materials

Saw Cutting

Prototyping

Thermal Deburring

Ultrasonic Washing

Stocking Programs

Machine Monitoring

MRP Programming

Value Add

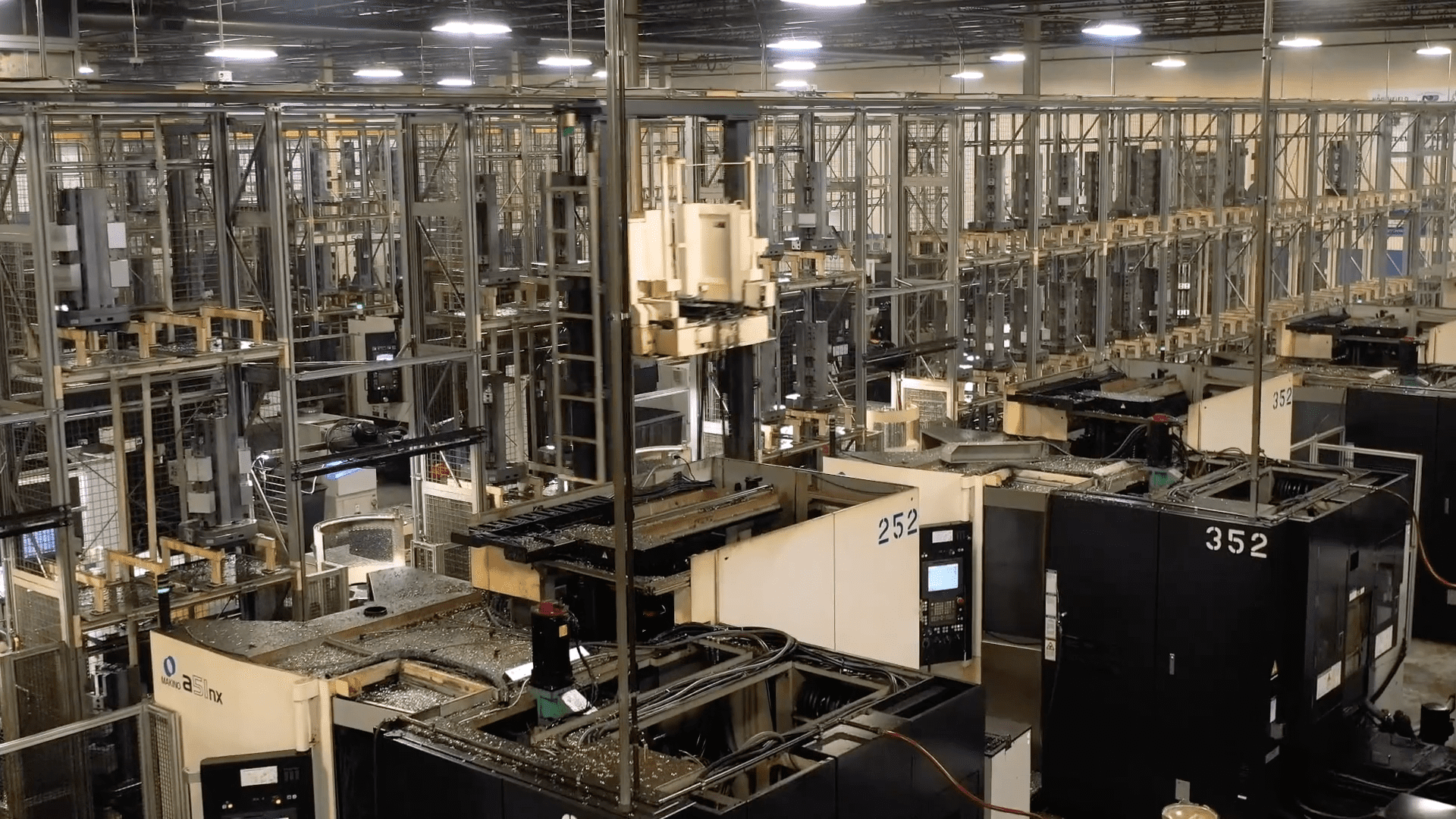

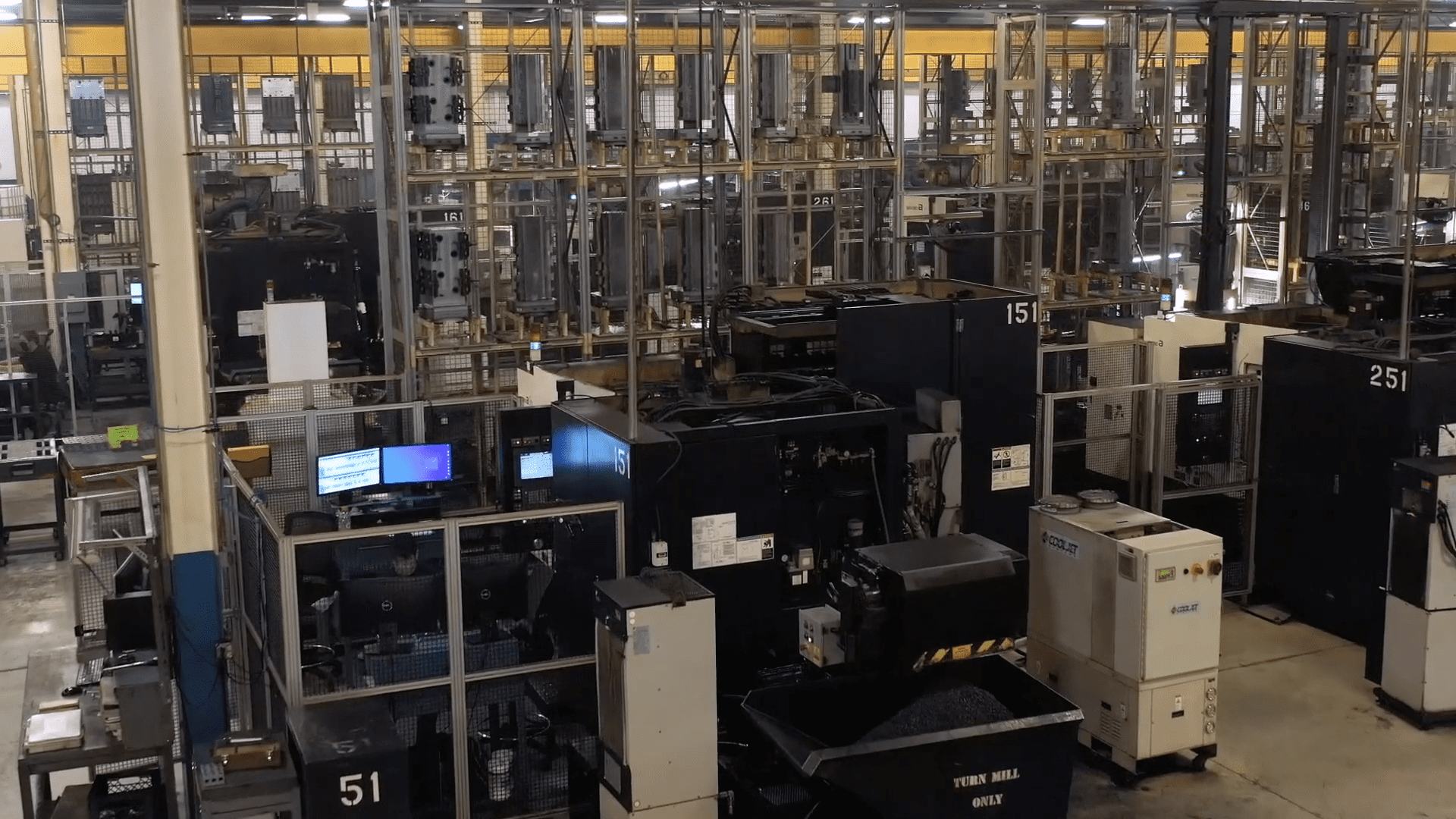

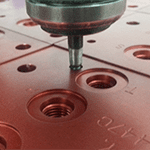

FLEXIBLE MACHINING

Our linear FMS, Flexible Machining Systems, gives us the ability to run repeat orders with no setup, making on-demand production a reality. Once a part is set up in our flexible systems, it remains resident allowing us to machine small quantities as efficiently as large runs.

Prototyping — 1 to 10 pcs.

Low volume to medium production — 10 to 100 pcs.

High volume capability production — 100 to 50,000 pcs.

MATERIALS

- 6061/2024 Aluminum

- Ductile Iron

- Grey Iron

- Steel

- Aluminum & Iron Castings

SAW CUTTING

Internal saw cutting and milling to drive out cost. New Dimensions has 4 High Precision Metal Saws currently in operation

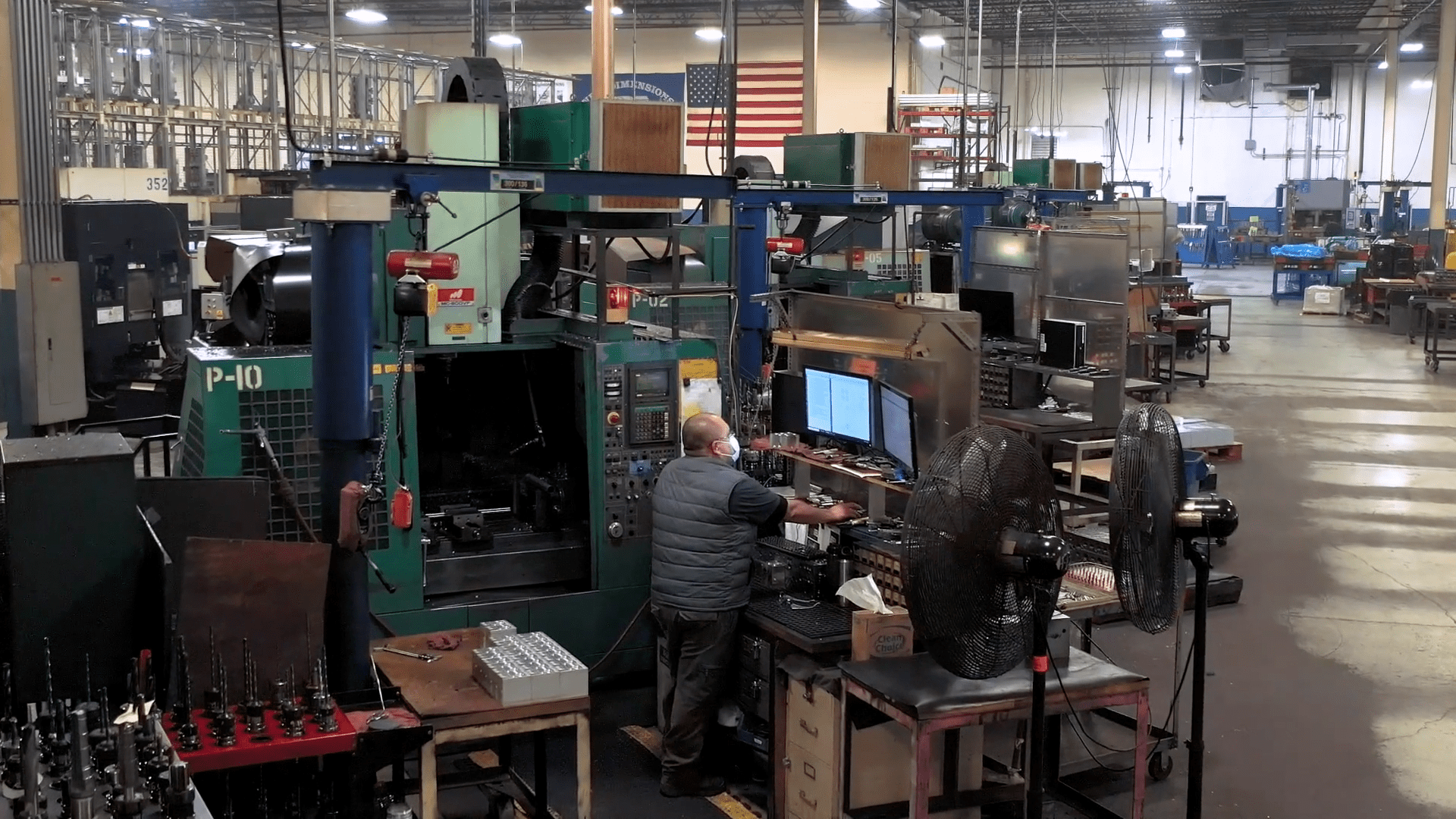

CNC PROTOTYPING

Dedicated Prototype department with 6 CNCs (2 to 3-week Lead-times)

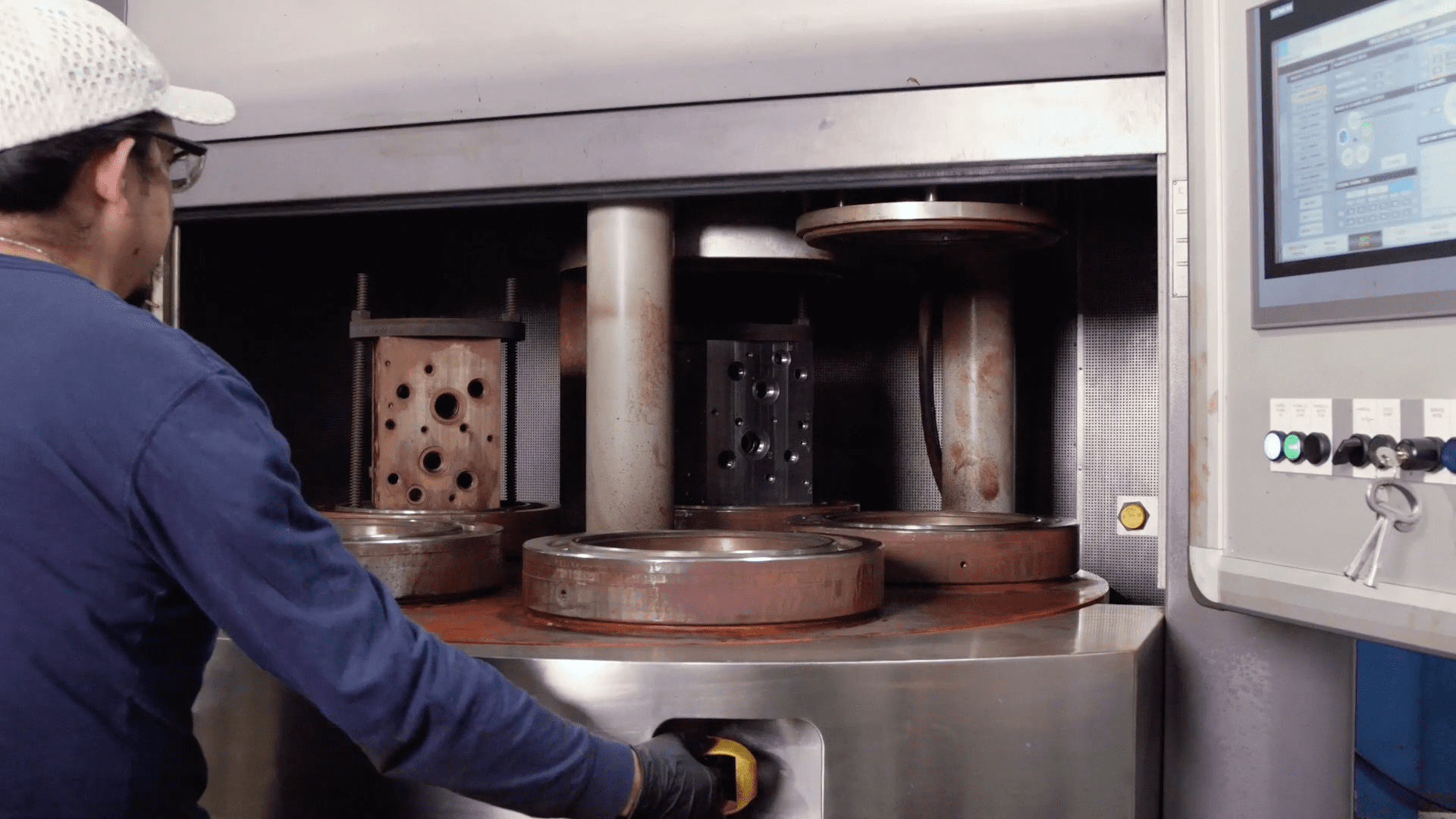

Thermal DEBURRING

Removing burrs and other particles from our customer’s products is very important. However, there are other important benefits specific to thermal deburring. Compared to manual deburring, thermal applications achieve a higher-quality deburr while also being able to repeat that success every time at scale.

Consequently, thermal deburring delivers more efficient, repeatable, and reliable results.

Ultrasonic washing

Four separate wash systems to meet individual cleanliness requirements.

Customized stocking programs

Consignment, KanBan, Min/Max Stock available with expanded warehousing.

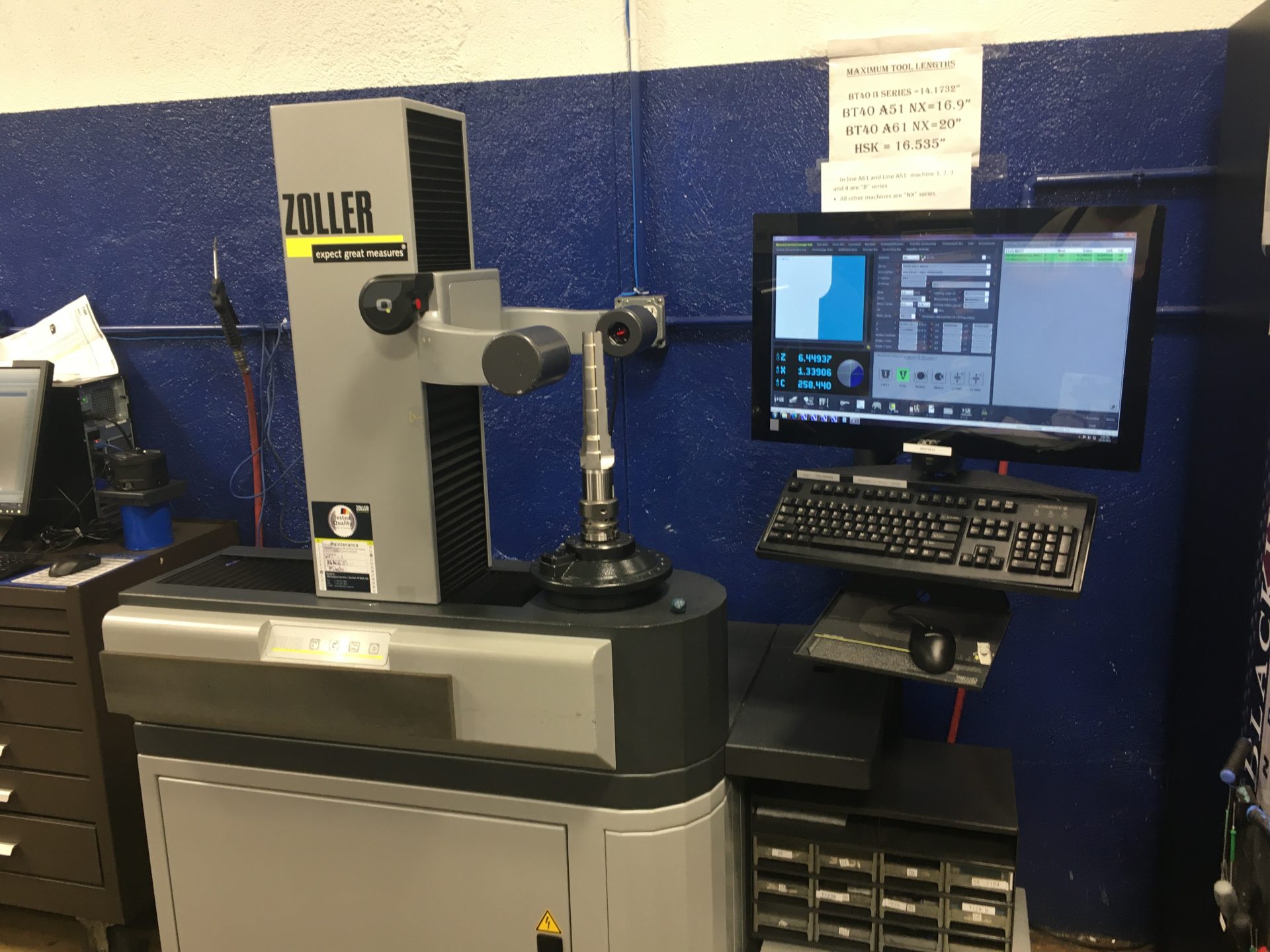

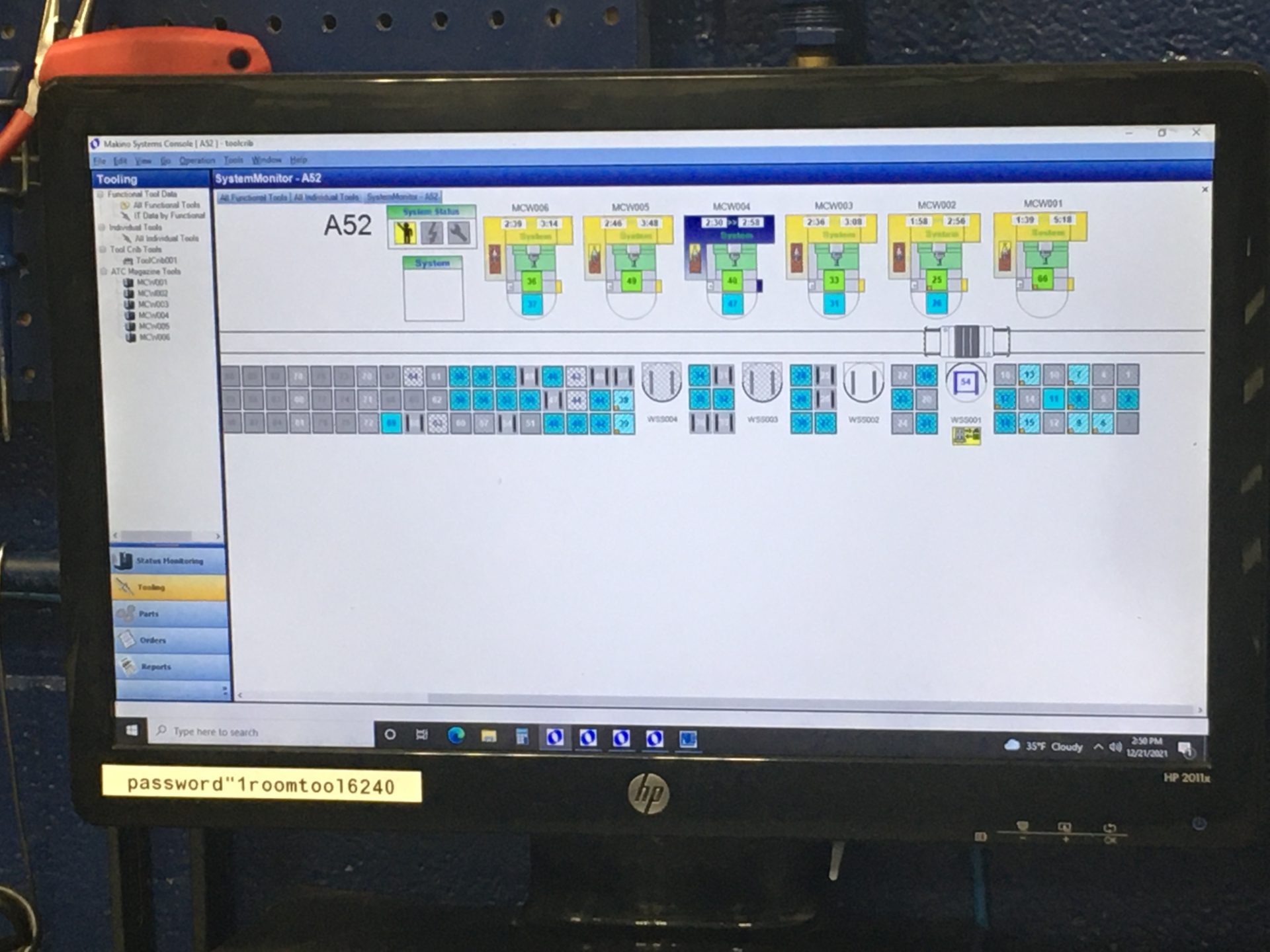

REAL-TIME MACHINE MONITORING

Our machine monitoring software gives real-time information to help maximize the efficiency of our equipment. This software combines our tool life monitoring, NC program storage, job scheduling, machine status, and more, into one system.

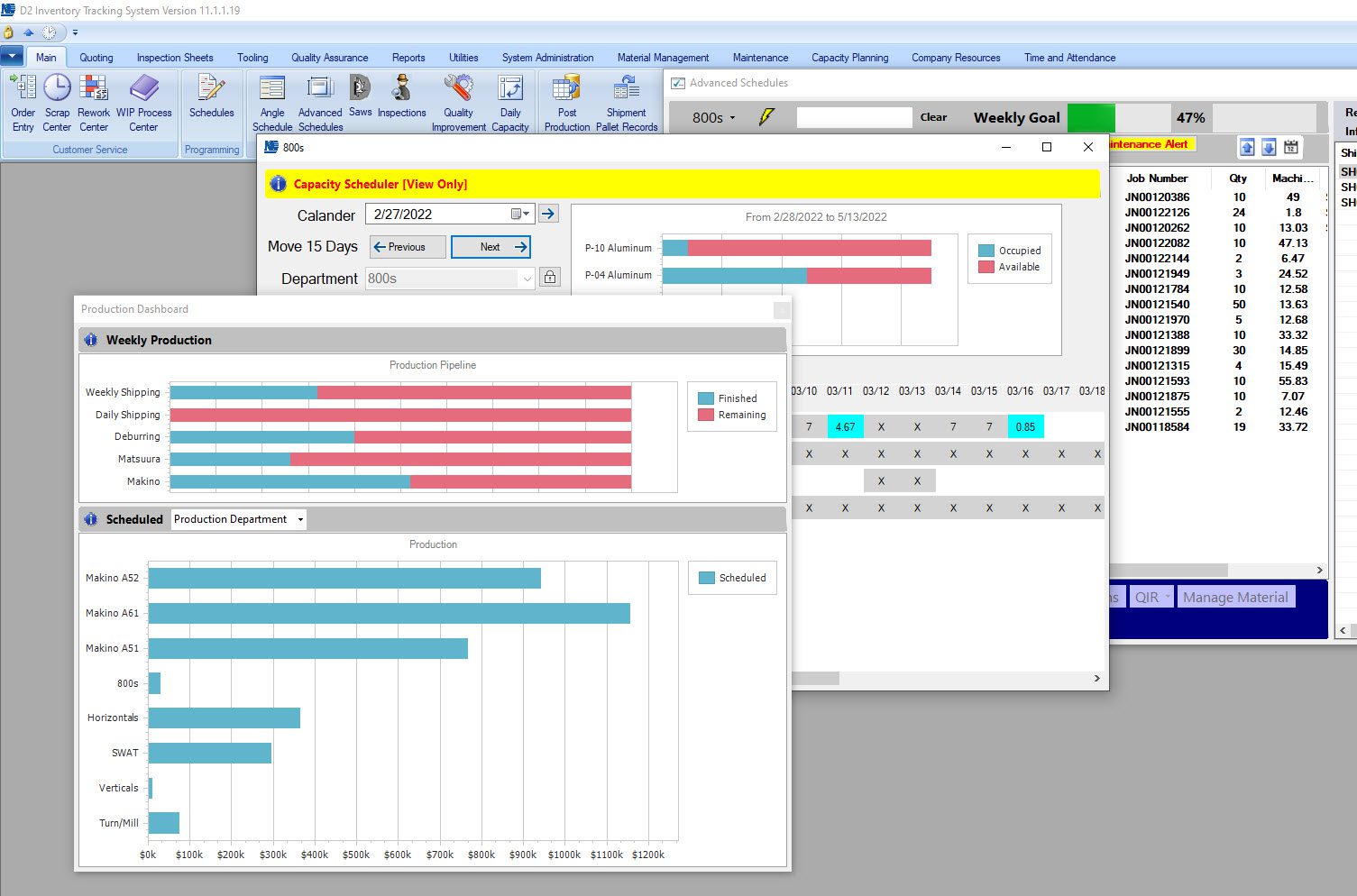

CUSTOM MRP PROGRAMMING

Our in-house software engineering department continually develops our custom MRP (Manufacturing Resource Planning) system which tracks all aspects of our jobs from quotation to shipment. This gives us the ability to custom tailor our software as our company and customer needs change, including customer-specific modules such as real-time part status updates, ASN (Advanced Shipping Notification) through EDI, and more.

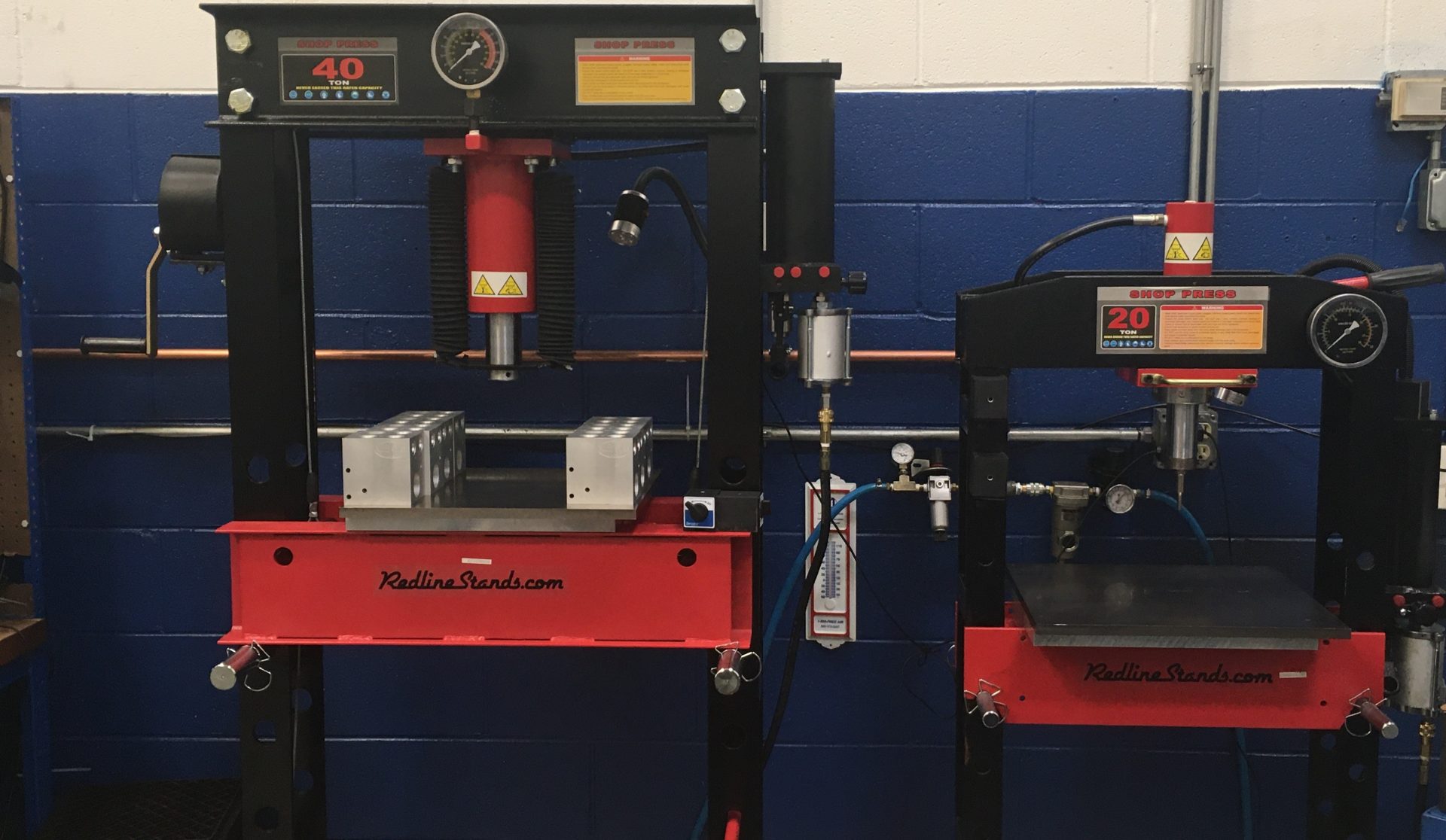

VALUE ADDED & Pre-Assembly Options

- Expander Plug Insertion

- Heli Coil Insertion

- Parts Bag Kitting

- SAE Plug Insertion