Quality Assurance

New Dimensions has invested significantly in its ability to provide quality products with the latest equipment, assure that every machined part is delivered on time with the highest quality.

At our plant, quality control is paramount from start to finish. Our Machining Systems and processes are created to meet rigid customer demands. We start with consistent suppliers and approved sources that know the needs of our customers. We apply the latest technology and processes including, SPC, TQM, and material traceability.

Having documented-controlled processes, experienced quality technicians and production teams we are able to meet your specific quality requirements. Through the use of various tools that include PPAP, APQP, FEMA and SPC, we continually and successfully guarantee that our commitments to you are met.

ISO 9001 CERTIFIED SINCE 2005

Copy of most recent certificate available upon request.

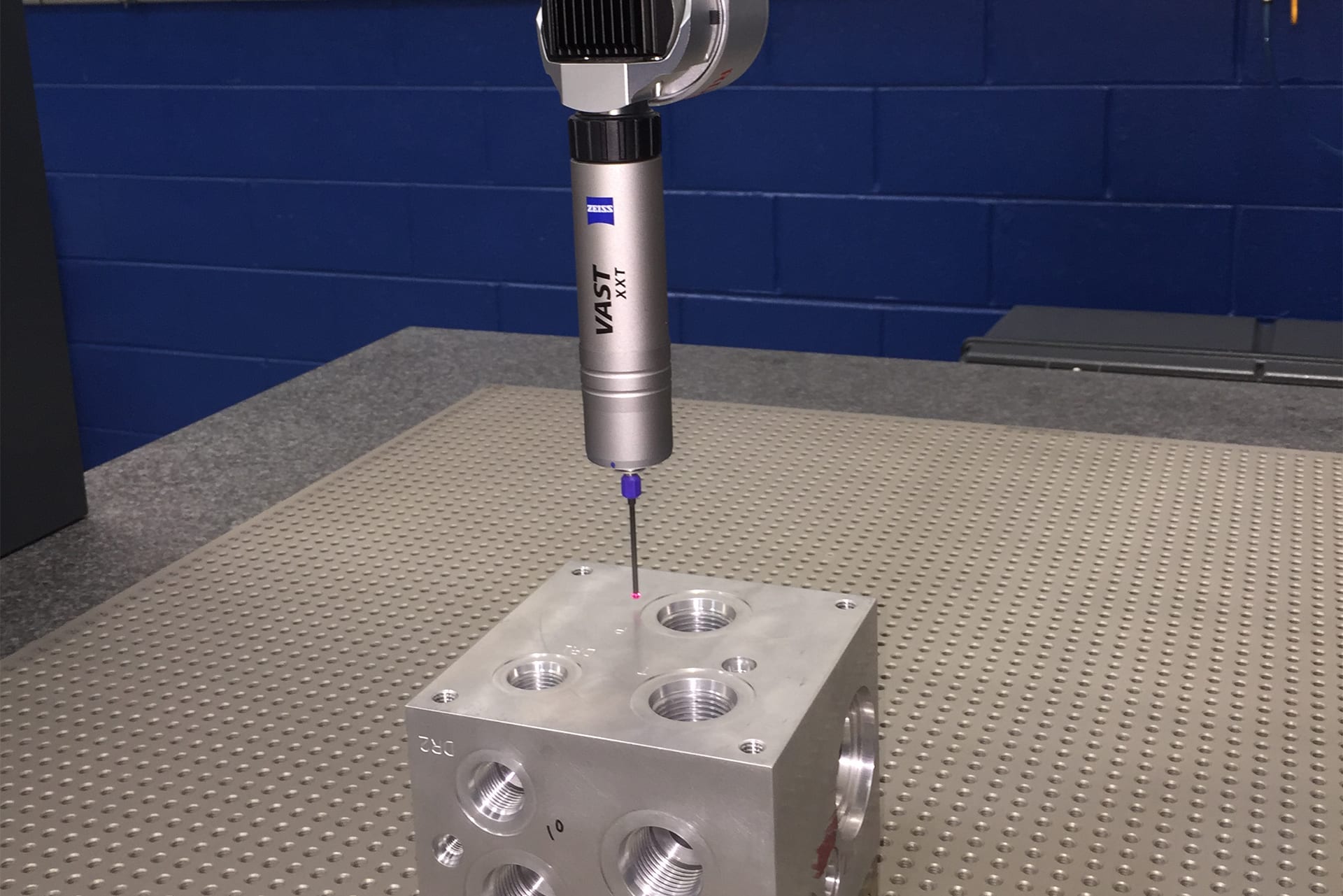

COORDINATE MEASURING MACHINE

We validate every aspect of the manufacturing process at New Dimensions by utilizing a Zeiss- Contura Coordinate Measuring Machine. Using coordinate measuring machine technology we are capable of reliably inspecting critical dimensions, difficult to measure features and GD&T requirements. With the latest programming software we can import 3D solid models and program full part inspection routines and validate capability.

HOW DOES NEW DIMENSIONS CONTROL ITS MANUFACTURING PROCESS?

Every part we manufacture starts with a complete team feasibility meeting, review of the print, tolerances, and customer specifications. Our team, consisting of sales, manufacturing, engineering, quality, materials and customer service work together to review the specific part requirements and customer expectations to insure full compliance. Our control documentation is created which includes setup sheets, bills of materials, tooling, gaging, testing requirements, as well as packaging specifications. Customers are encouraged to attend our kickoff meetings to add any insight, experience, or knowledge which might be useful.

DIGITAL TOOL MEASURING AND INSPECTION Equipment

New Dimensions focus and commitment to quality now includes a ZOLLER digital tool measuring and inspection machine. New Dimensions measures tools to two-thousandths of a millimeter — quickly, simply, accurately and guaranteed! Accuracy means less waste, less CNC machine down time and the best quality products in the market.

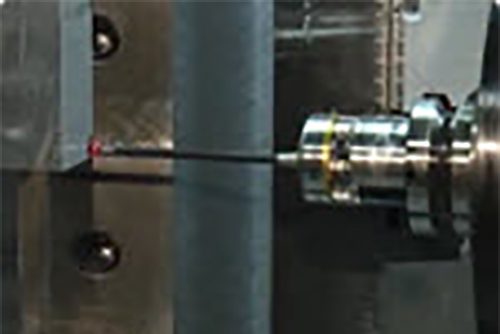

IN-SPINDLE PROBING

To ensure dimensional accuracy we have machines equipped with in-spindle probes. These probes are programmed to measure and make adjustments to compensate for any variation in material, part loading, fixturing, etc. These probing systems can accurately measure to .00005”.

TOOL LIFE MONITORING – INFARED 30X CAMERA

Our machines are equipped with today’s newest technology in tool life control, giving us the advantage of predictable quality during production. Using a presetter with a high resolution digital infrared camera, we perform continuous in depth tool analysis. Based on the wear analysis we can establish accurate tool SPC to proactively eliminate scrap and maintain a reliable process.

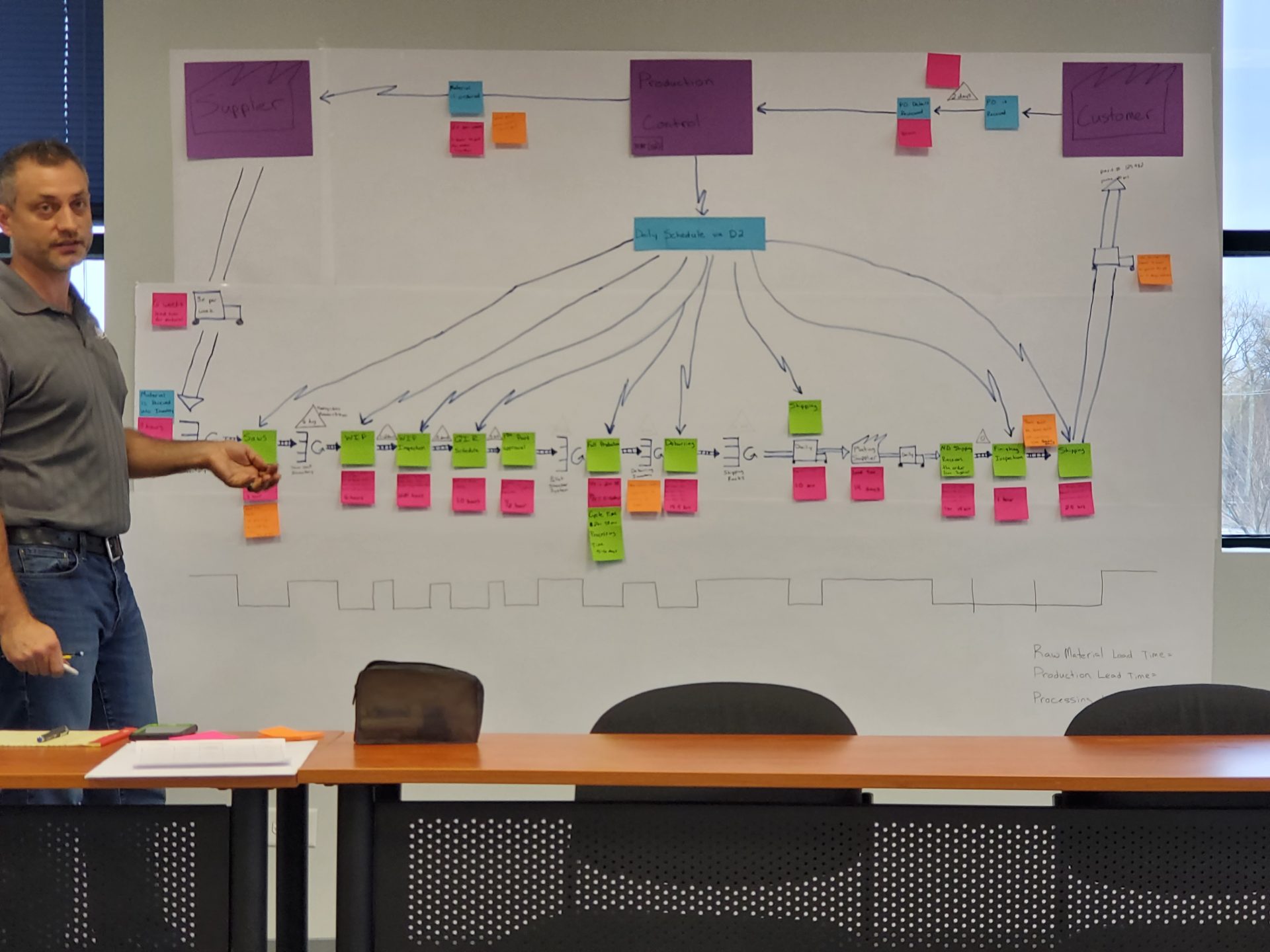

SIX SIGMA CULTURE

Six Sigma Culture with Five Six Sigma Black belts leading & driving continuous improvement throughout the organization.